Process Burners

Have you been searching for a way to reduce emissions and energy used for process heating while increasing the productivity at an energy-intensive plant? Are you looking to select a combustion system that will suit the particular requirements of an application?

Our specialists are here to examine your processes and suggest the most efficient and cost-effective way to help reduce your energy bill. Here at Nu-Way Energy, an industrial combustion burner can be sized and designed to suit the specific requirements of an application, offering a purpose-built solution to a problem whether it involves making steel or heating ladles, melting aluminium or heating your tanks. The systems can be incorporated into new applications or retrofitted to existing equipment, where they may overcome restrictions to production levels created by ancillary elements such as the bag house.

Lanemark FDB burners are able to provide up to twice the heat output when compared with the DB alternative and they can also be operated within a wider range of variable process air flow conditions.

LanemarkFD-C series burners are particularly suited to direct-fired applications and can be mounted directly on to the wall of a dryer, oven or process air heating duct to operate either in line with or to the process air flow.

Lanemark FDE series offers a cost-effective alternative to the FDC units while still delivering a full range of performance benefits.

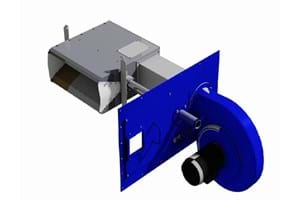

Lanemark FDGA series packaged burners offer flexible, high turndown (gas and air) control for process air heating applications

Lanemark Midco HMA2A series air heating burners are designed to provide a high efficiency, high turndown, low emission solution for air replacement or air heating applications

Lanemark TX series high efficiency, small diameter immersion tube tank heating systems offer end users the most cost effective method of heating process liquids which are used in many areas of industry.

The Nu-way ENERGY STREAM burners represent a new concept in direct-fired air heating. They are nozzle mixing line type modules, available in a straight or cross pattern that can be built into an infinite variety of patterns to suit duct dimensions and app

Nu-WayÊis a well-known name for industrial process burners. The MULTIPLEX burner has been designed to achieve high stability over a wide turndown range of relatively low service inlet pressures.